MANUFACTURING

Making luxury watches and jewelry is a tremendous challenge. Our teams shape gold, steel and ceramics to design the different components of our products. Links, clasps, rings and cases come to life, made from metal bars or powder. The handcrafted by man put the finishing touches on each component, making gleaming and incomparable products.

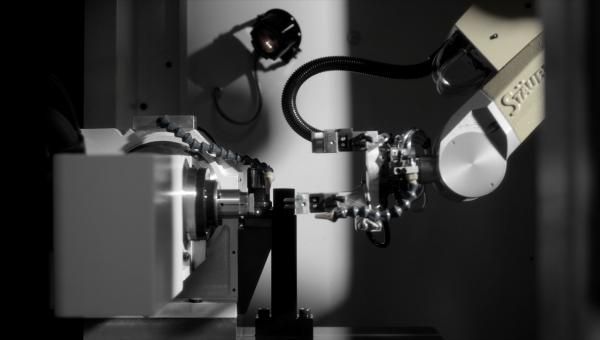

Our flexible industrial tools are created for the manufacture of single components as well as for the creative production of large series. This unique skill allows us to unleash new creative manufacturing concepts to create new shapes.

Machining is the first step in manufacturing a product and is performed by Computer Numerical Control (CNC) machines. Programmers, regulators, and operators ensure optimum function of technology.

Once the parts are machined, the watches or jewelry are adorned to perfection with precious stones by highly skilled gem-setters.

The last step before assembly is the finishing process. A mechanical preparation may be carried out by CNC machines. The parts then pass through expert hands who use mirror polishing, sandblasting, or satin-finishing methods for the final appearance. A team called “Visitors,” checks the final parts, ensures customer satisfaction.

These same steps are followed for the manufacture of ceramic parts. Chatelain possesses an undisclosed method for injection or sintering, executed by high-precision workers.

The Maintenance Department is also in the center of production: highly trained technicians are responsible for the installation and maintenance of our precision equipment, ensuring optimum function of installations.